Here's a basic math question for you: Sammie has 50 sprockets. She sells eight of them. How many sprockets does she have left?

Now, here's another question: Sammie has 50 sprockets. She receives an order for eight sprockets and ships four of them out to customers. How many sprockets are in Sammie's inventory?

These types of questions aren't just relics of elementary school -- they're also challenges inherent to inventory management. And it's the reason Sammie has 42 sprockets at the end of the first question but 46 sprockets at end of the second.

Inventory management goes beyond simple arithmetic. Sammie has 46 sprockets in her inventory because she only subtracts four of the eight sprocket orders until the other four are delivered to customers. It's this kind of contingency that makes organization, automation, and technique crucial when you have so much product to keep track of.

To help you dive into inventory management, let's explain what inventory management is in the ecommerce world, the software that supports this ongoing process, and some common techniques for managing inventory successfully.

Inventory Management Definition

Inventory management is the act of overseeing the volume, diversity, pricing, and location of a business's available products. If a product is in stock, it's counted as part of the business's inventory and managed as it moves through the supply chain.

The product's availability is then noted on the item's purchase page online.

This is why, in our example of Sammie's 50 sprockets, she still has 46 sprockets after selling eight. Knowing what's currently in her inventory, how many units of her product have been ordered, and how many units her inventory is shipping and receiving is all part of basic inventory management.

Inventory management does not include company property, manufacturing equipment, and other forms of business capital. It can, however, include separate parts of a product that has not yet been assembled for a customer. How these parts are counted in relation to the finished product depends on the form in which the product is delivered to the customer.

Inventory Management Software

As your business grows, it will inevitably become harder to manage inventory manually -- especially if you sell online, where your customers expect to see a product's availability and status at every point in the buying process.

Luckily, there are numerous inventory management tools on the market today that integrate with an ecommerce website and help you monitor your supply chain. To make your software choices easier, we've listed seven of the best solutions for ecommerce businesses below.

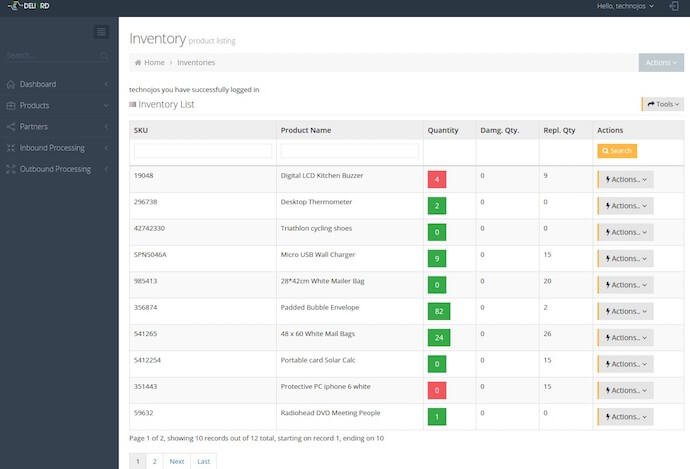

Delivrd

Price: Free

Delivrd is a free cloud-based order-fulfillment solution for businesses of all sizes. The platform tracks your inventory, prints barcodes, analyzes each product's profitability, and even bundles unfulfilled orders together to consolidate future shipments.

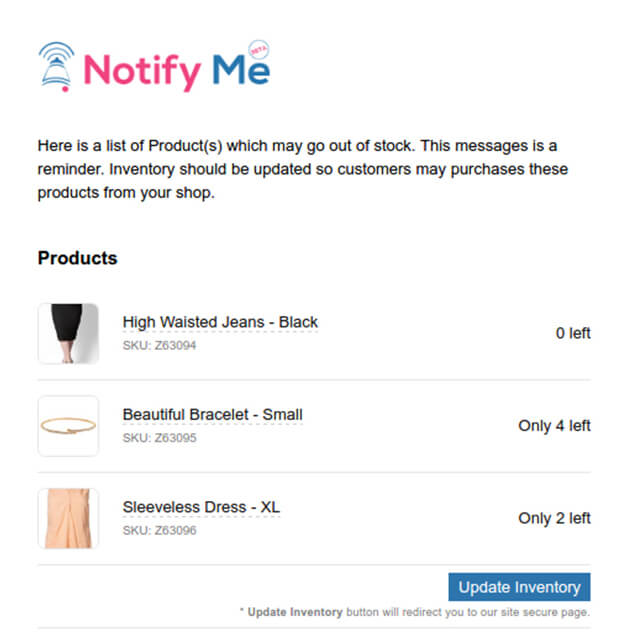

Notify Me

Price: Free

Notify Me is a free inventory manager for ecommerce businesses who use Shopify as their sales channel. In addition to watching over your store's available products, Notify Me uniquely allows you to set automated alerts for when items go out of stock. Shopify users can download the web app here.

Oberlo

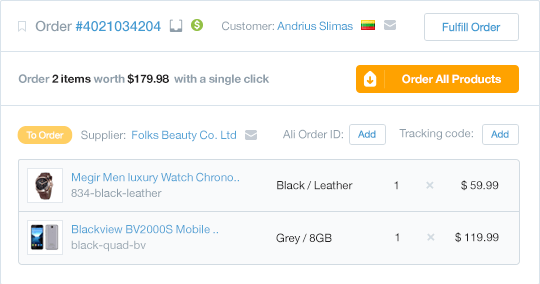

Price: Free up to 50 orders/month

Oberlo is one of the best inventory management services for dropshipping stores -- or those ecommerce businesses that deliver products directly to the customer from a manufacturer, without storing any product on-site. You can create rules for when to reprice products, sort products by their delivery times, track shipments, change product suppliers, and more. Oberlo also has a web app for Shopify users.

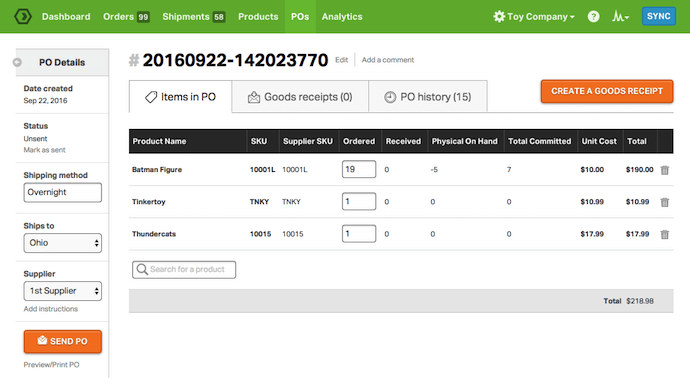

Ordoro

Price: Starts at $25/month

Ordoro is a cloud-based shipping tool for managing inventory at every point in the sales process. The service automates shipping requests, dropshipping, barcode scanning, and supplier management -- and can provide revenue data in real time. Ordoro integrates with more than two dozen sales channels and shipping carriers. It also has a web app for Shopify users.

inFlow

Price: Starts at $69/month

You get a lot for what you're paying when you use inFlow. This cloud-based inventory manager organizes bills, barcodes, work orders, product serial numbers, product destinations, and more -- whether the item is in your inventory or in transit. In addition to working offline, inFlow also offers robust Windows and Android apps to manage your inventory from your mobile device.

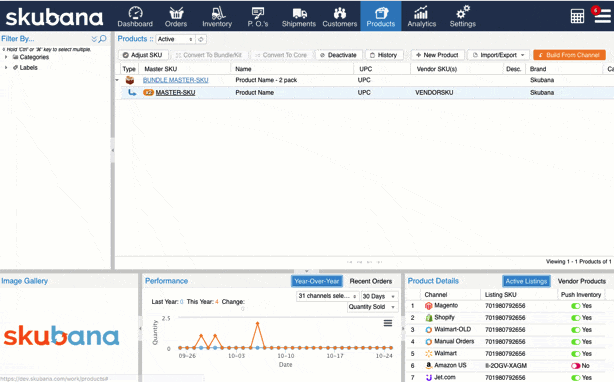

Skubana

Price: Request a Quote

Skubana connects your ecommerce business with retailers all over the world. The software helps you manage customer orders and your own restocking process, while integrating with the retail brands who might also want to sell your product. Skubana tracks order fulfillment from multiple warehouses and generates demand forecasts that help you grow your product line. It also has a web app for Shopify users.

Unleashed

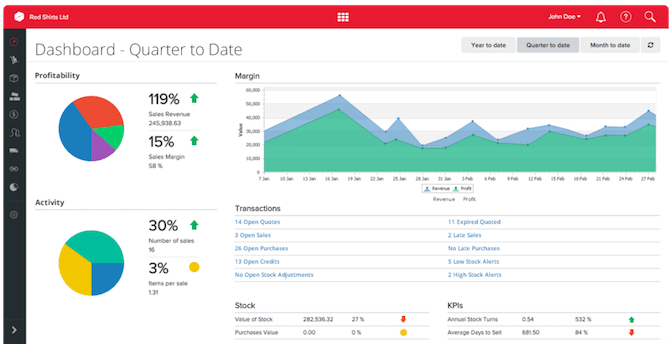

Price: Starts at $85/month

Unleashed is a sleek, flexible inventory management solution that allows ecommerce customers to make big decisions about their product line based on real-time data. The software is perfect for manufacturers, according to Unleashed's website, and offers the most important inventory information in a convenient sales app for your mobile device.

Inventory Management Techniques

Although a business's available stock on any given day is just a snapshot of its inventory, managing inventory on an ongoing basis -- and comparing multiple periods of inventory to one another -- can help an ecommerce business make valuable long-term decisions about its supply chain.

Ecommerce companies can manage their inventory in several ways, but not every method of management will provide the insight you need to help your business grow. Here are a few different inventory management techniques you can try, and the advantages of using each one.

Just-In-Time

This inventory management technique stocks a product each time a customer orders it, so the volume of your inventory is more or less equal to the number of orders you're filling.

The advantage to the Just-In-Time (JIT) technique is that you're managing only the products you know you need to ship to customers. Sustaining JIT over the long term, however, requires you to keep a close watch on buying behavior so you can anticipate your inventory needs ahead of time.

First In, First Out

First In, First Out (FIFO) means the first products your inventory receives are the first to be shipped out to their respective customers.

This technique ensures products don't sit in your inventory for too long before they're delivered to a customer. FIFO is popular in the food industry, where businesses are up against the expiration dates of perishable items and need to ship food while it's fresh.

Par Levels

Setting par levels gives businesses a safety net by ensuring their inventory always carries a minimum amount of each product at all times. So, even if a company uses the JIT method, where it only stocks what customers order, the company will always have the product available.

Ultimately, par levels aren't for emergencies where you'd need a spare product. Rather, they establish a warning line for when it's time to order more of something. Once your inventory dips below a certain number of a given product, you order more of it.

It's important to set your par levels based on how long it takes to restock. The product that takes the longest time for a business to make, for example, might have a higher inventory par level than the business's other products since there's a greater chance of depleting your inventory in the time it takes to develop the new product.

ABC Analysis

ABC Analysis groups a business's products into three categories based on a product's importance. Here's one common breakdown of these categories:

- Category A: products that are high in value but low in quantity

- Category B: products that are moderate in value and moderate in quantity

- Category C: products that are low in value but high in quantity

Also known as "selective inventory control," this inventory management technique allows businesses with diverse product lines to easily prioritize the contents of their inventory. Similar to the JIT technique, succeeding under ABC analysis requires a close eye on buyers' interest in each product, and not every product fits perfectly into each category. Snowboards, for example, might always have the high value of Category A, but inherit the high quantity of Category C during the winter.

Dropshipping

In a way, dropshipping is the anti-inventory. A specialty of Oberlo, an inventory management tool mentioned earlier in this article, dropshipping ships products from the manufacturer directly to the customer without the business ever storing the product itself.

Dropshipping can pose an advantage to businesses who don't (yet) have their own storage space. But because you're not managing your deliveries yourself, communication with the shipping party is critical to delivering products on time and keeping customers happy.

Demand Forecasting

Your inventory management software might help you do this, but it's important to create long-term (or even year-long) forecasts for when sales of each product you sell will fluctuate.

One way to conduct a demand prediction? Look at last year's sales as a whole and use them as a guideline for when to expect your inventory to change over the course of the current year. These changes might be influenced by market conditions or simply seasonality, but you should always factor them into your product strategy -- especially if the software you use to automate your inventory operations doesn't consider these variables.

Here's one final inventory management tip to take with you: Nurture your relationships with everyone who touches your business's product. Whether it's the shipping merchant or a new employee, the state of your inventory depends on you to have open communication with your colleagues, and to support them as much as you support your customers when they browse your online store.

from Marketing https://ift.tt/2IthzU1

No comments:

Post a Comment